- Chutney House Brings Authentic Indian Fine Dining to the Heart of Windsor

- MUGSHOT Meme Coin Launches with Viral Energy and Community-Driven Hype

- Initial Phase of Bihar Special Intensive Revision Completed

- Hawaii Insurance Agency Releases Guide on Building a Business Disaster Recovery Plan

- Cluffy Insoles to Attend USA Cheer 2025

- Aamir Khan attends exclusive screening of Sitare Zameen Par at Kanha Shanti Vanam

- Indo-Palau Film and Cultural Forum Showcases Island Heritage Through Fashion at 9th Global Fashion and Design Week

- Codes For Tomorrow Announces Major Upgrade to Its Cryptocurrency Wallet Development Services with Limited-Time Pricing Offer

- Infinix to Launch HOT 60 5G+ with Groundbreaking ‘One Tap AI Button’

- Diamond D Construction Launches Specialized Construction and Fire Prevention Services in South Lake Tahoe

- Renowned British Producer Jonny Persey Conducts Inspiring Workshop at Marwah Studios

- Winners announced for the Australian Government’s Study Australia Entrepreneurship Challenge 2025 India

- Aakash Education Signs MoU with CRPF Family Welfare Association to Offer Scholarships and Mentorship Support to CRPF Families

- Taneira expands its presence in Delhi NCR with its newest store

- Softaken Announces the Release of Its All-in-One Audio Video Converter

Mail to a Friend Mail to a Friend |

|

|

New FlyPOD option by Seica allows connecting multiple hardware resources to a mini fixture

Strambino; May 2021, -- The complexity and miniaturization of electronic boards leads the market to an increasingly widespread deployment of flying probe testers which are turning from parametric testers into powerful and flexible general purpose testing platforms, with unimaginable potentials even in a not too distant past. The heads of a modern flying probe system can be equipped with electrical flying probes but also with different types of tools, drastically increasing its potentials.

The On-board programming is a crucial step in the electronic board testing.

Even for low-volume production, the following factors are involved which make essential the integration of the programming stage in the automatic test process:

? Management of data confidentiality

? Objective definition of the correct release to be installed

? Optimization of the programming times

? Need to reduce board handling

Seica?s Flying Probe Solutions

Following the winning philosophy which characterized its business in testing over three decades, based on the constant and rapid innovation of its testing solutions, Seica has introduced the PILOT NEXT>Series line. This is the new generation of flying probers featuring a renovated and sleek look thanks to the premium materials of the chassis, and innovative electrical worth discovering performances, undoubtedly the most complete flying probing test platform on the market.

New FlyPOD option by Seica ? available now !

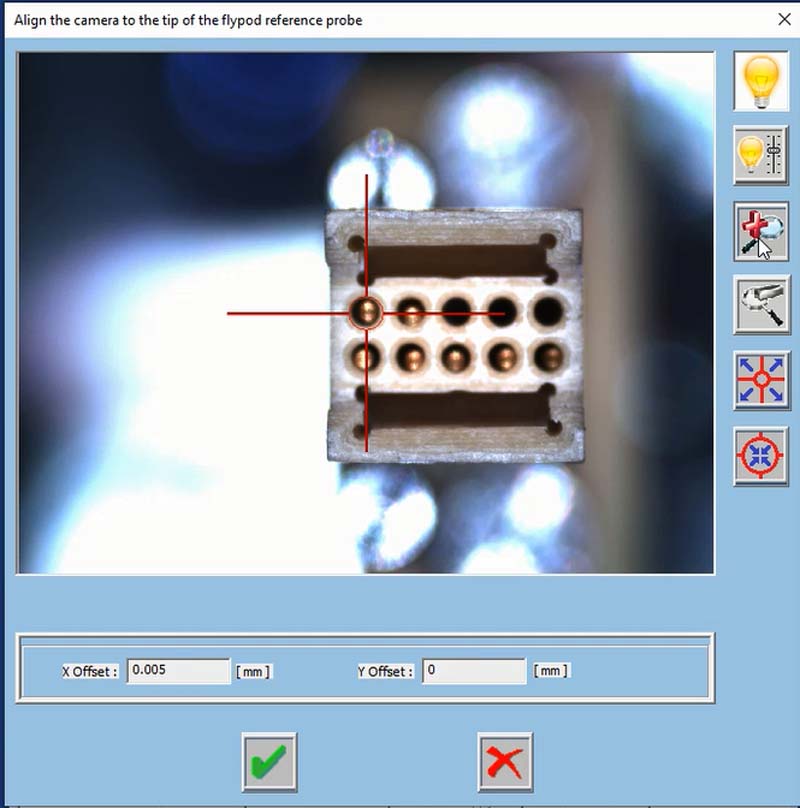

In this context it is worth mentioning the new FlyPOD option by Seica, which allows to connect multiple hardware resources to a mini fixture which is installed directly on one of the flying probes. The FlyPOD module is mainly conceived and deployed for the On Board (OBP) programming, as a boundary scan test interface or as communication interface (e.g. CAN, I2C, ?).

Implementation characteristics:

? Automatic flying prober with a 4 or 8 probes with FlyPOD option, can be perfectly integrated into a high-volume automatic production line.

? Integration of up to 2 FlyPOD on different heads for OBP programming, Boundary scan, CAN communication and other purposes.

? Fixture with minimum step of 1.27 mm (5?5 grid)

? Max. number of contacts: 14

? The D.U.T. should provide a termination of test points connected to the device to be programmed

? The mini-fixture are plug & play type, and will be manufactured according to the configuration in use.

Benefits

? Fast and reliable programming: the solution ensures a minimum distance (~30 cm), between the target and the programmer; which is directly installed on an interface board attached onto the FlyPOD.

? Optimization of the programming speed with respect to a centralized programmer (inappropriate cable length).

? Possibility to double the FlyPOD heads and perform programming in parallel.

? Integrated software management, demanded to the Seica VIVA software.

? Dynamic script of the board serial available

? Automatic selection of the release to be installed.

? Verification of the correct programming and reporting.

? Possibility to add programming- related functional tests

Moreover, all the PILOT NEXT>Series testers feature the Industrial Monitoring solution ?4.0 ready? by Seica, to monitor current absorption, supply voltage, temperature, light indicators and other parameters useful to indicate the correct operation, to ensure predictive maintenance and make the systems compatible with the new standards of the fourth industrial revolution ongoing nowadays.

About Seica

Founded in 1986, Seica S.p.A. is a global supplier of automatic test equipment and selective soldering systems, with an installed base of more than 2500 systems on 4 different continents. Seica offers a complete line of test solutions, including bed of nails and flying probe testers able to perform MDA, in-circuit and full functional tests of assembled electronic boards and modules and printed circuit boards, as well as LASER-based selective soldering systems for electronic board manufacturing and a full range of test application services. Company headquarters are located in Strambino, Italy, with direct offices in USA, Germany, China, Mexico and France, supported by a vast distribution network covering the rest of the world. Since 2014, Seica S.p.A. is supported by a sister company Seica Automation, located in Milan, and producing board handling systems and other automation equipments for the electronic manufacturing industry

Company :-RF Communications

User :- Renate Fritz

Email :-renate.fritz@onlinehome.de

Other articles by Seica