- ThoughtSol Infotech is Certified as the 'Great Place To Work' in the Fifth Consecutive Year

- Samsung India Launches the 2nd Season of 'Samsung Innovation Campus' National Skilling Programme to Empower Youth

- HCLTech appoints Lee Fang Chew as Independent Director

- Princeton Psychotherapy Center Introduces Innovative Therapies for Breakups and Chronic Pain

- MindCypress Hosts Successful IFRS Webinar for Finance Professionals

- Kirill Kupchenko, Director of After-sales Services at AVTODOM MKAD, spoke about the service of electric vehicles Zeekr

- Advertising Maverick Tridib Ghosh Launches Game-Changing Advanced Generative AI Course

- CLIRNET Teams Up with African Medical Associations to Revolutionize Healthcare Education

- Grossman Chevrolet to provide Old Saybrook Little League with new equipment, monetary contribution

- Motion Education aces the JEE exam, recording a selection ratio of 68.01%

- Mars Wrigley launches BOOMER Jelly on Top Boomer, Goes Wobbly with Bumrah for Maximum Fun

- The Shoreline Unveils Premier Co-op Apartments in New Rochelle, Redefining Luxury Living

- Vedanta FACOR and CFlo Partner for Sustainable Chrome Beneficiation in Odisha

- Authorized Economic Operator (AEO) Status Now Extended To The Gem & Jewellery Sector

- Cocobellacb.com Reveals Blooms That Last: A Guide to Selecting the Ideal Faux Floral Shop for Faux Arrangements

Mail to a Friend Mail to a Friend |

|

|

Intelligent networking: Big data enabling a new standard in SCHOTT’s pharmaceutical glass manufacturing

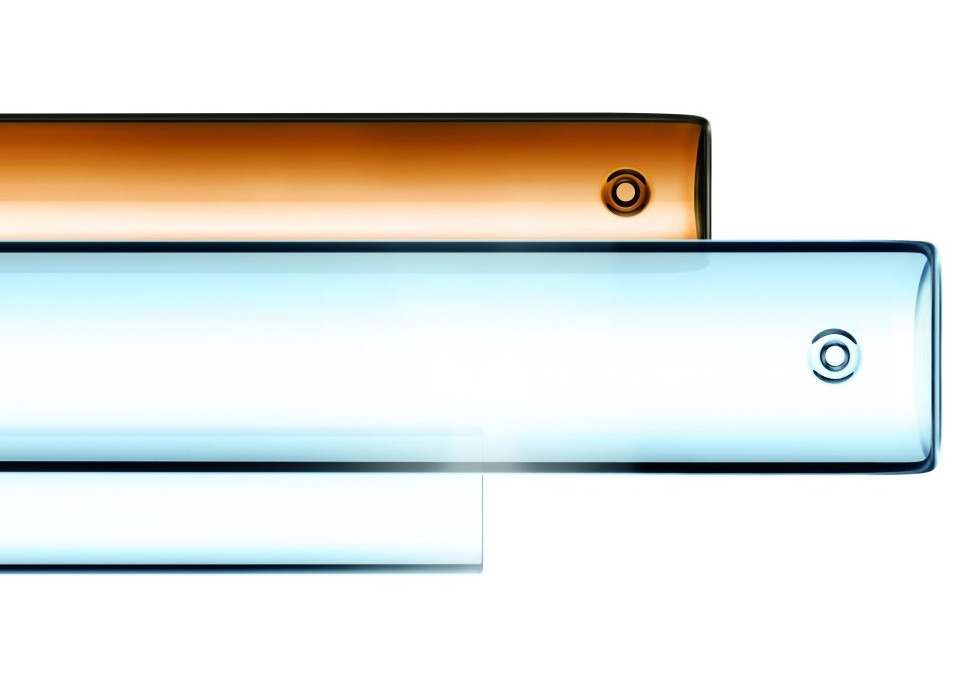

Mainz/ Jambusar, August 30, 2017: SCHOTT has recently integrated a specially developed big data solution into its pharmaceutical tubing production in India, replacing statistical sample-based quality assurance with 100 percent on-line measurement.

With the new IT-based process called perfeXion?, process- and product-quality data of each individual glass tube is collected online and in real-time ? an innovation that sets new standards in the pharmaceutical glass industry.

During the multi-layered process of pharmaceutical tubing production, statistical quality control is not 100% thorough. However, thanks to a unique big data approach, SCHOTT Glass India is now able to measure 100% of every single glass tube in production. Instead of selecting a few glass tubes from each batch for statistical quality control, the new perfeXion? system measures the entire glass tube many times over as it is drawn from the melt. Lasers recognize deviations in diameter and wall thickness, for example, and camera and IR inspection systems can even detect the smallest inclusions in the glass. Around 100,000 data tags are generated every minute. An integrated IT system, evaluating the continuous glass tube with real-time data measurements, calculates incidents of imperfection with such precision that it can later differentiate corresponding individual tubes which can then be sorted out. Each tube is checked again at its completion.

?This data enables for post-processing steps to be efficiently aligned with the tubing quality. With big data, the international technology group is creating a new industry standard and raising the quality of pharmaceutical glass production to a new level,? said Mr. Sundeep Prabhu, Vice President Sales and Marketing, SCHOTT Glass India Pvt. Ltd.

The system?s development took several years. Analyzing a curved tube surface zooming down a production line was a particularly difficult challenge. The effort, however, has paid off ? not least because the data analysis is a source of insight into how production can be further optimized.

Every year, SCHOTT produces about 150,000 tons of glass tubing worldwide, most of which is destined for pharmaceutical packaging. Thanks to the new perfeXion? approach, quality data can be traced back more detailed along the value chain. ?There comes a particular responsibility being a pharmaceutical industry supplier, and traceability is a major issue in the industry,? says Dr. Patrick Markschl?ger, Executive Vice President at SCHOTT Tubing. ?By gathering information on each individual glass tube, we?ve already made an important contribution to quality assurance for downstream post-processing steps at the very beginning of the value chain.?

Data usage opens new potential

?Companies that want to systematically control their production to make it more efficient in the long run can?t afford to miss a strategic use of production data,? adds Dr. Frank Heinricht, Chairman of the Board of Management at SCHOTT AG. ?Making intelligently linked data available to others not only optimizes processes ? it creates new creative potentials for product and process development.? The system is tailored for production of glass tubing, but other areas of the company can certainly benefit from the findings in the medium-term. SCHOTT?s perfeXion? has been installed at all its tubing lines globally, including its India plant in Jambusar, Gujarat, where the system has been implemented from July 1st onwards.

India?s Pharma Outlook

The Government of India has unveiled its aim to make the country a global leader in the pharma manufacturing sector with \'Pharma Vision 2020\'. Constant innovation is key to achieving this vision, with state-of-the-art-technology and corresponding know-how guaranteeing the same. This implies efficient pharma packaging, and advanced allied technologies by pharmaceutical companies, research labs, and other stakeholders. For pharmaceutical packaging, utmost precision and accuracy needs to be maintained at every step of the process in making the required glass tubes such as vials and syringes.

About SCHOTT:

SCHOTT is a leading international technology group in the areas of specialty glass and glass-ceramics. The company has more than 130 years of outstanding development, materials and technology expertise and offers a broad portfolio of high-quality products and intelligent solutions. SCHOTT is an innovative enabler for many industries, including the home appliance, pharma, electronics, optics, life sciences, automotive and aviation industries. SCHOTT strives to play an important part of everyone?s life and is committed to innovation and sustainable success. The group maintains a global presence with production sites and sales offices in 34 countries. With its workforce of approximately 15,000 employees, sales of 1.99 billion euros were generated in fiscal year 2015/2016. The parent company, SCHOTT AG, has its headquarters in Mainz (Germany) and is solely owned by the Carl Zeiss Foundation. As a foundation company, SCHOTT assumes special responsibility for its employees, society and the environment.

Company :-CNC India Pvt. Ltd.

User :- Vidhu Goyal

Email :-vidhu.goyal@cnc-communications.com